4 in 1 Laser Weder Cutter Cleaner 1kw 1.5kw 2kw 3kw Factory Supply

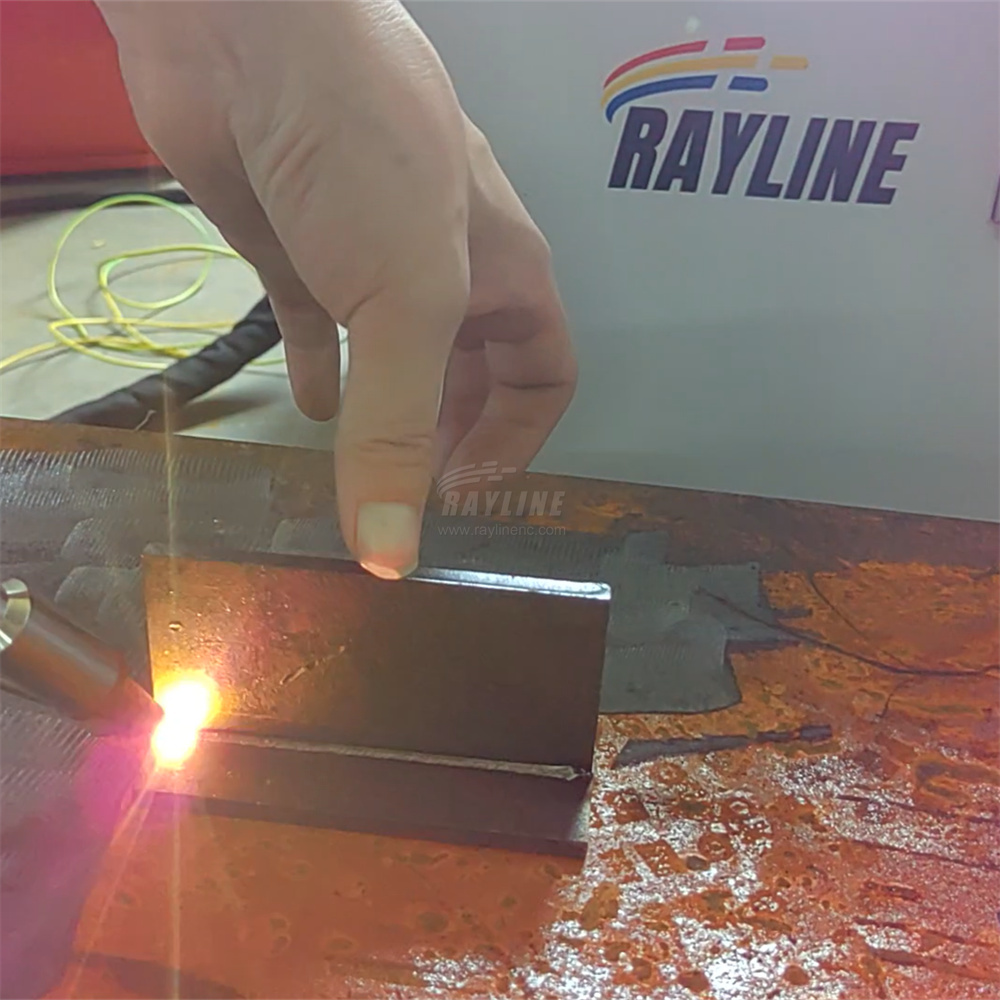

4 in 1 handheld laser welding machine is a new generation of laser welding products. The machine adopts a four-in-one color touch screen system, which can realize functions such as cutting + welding + cleaning. One machine with multiple functions can meet various application scenarios. The laser of the machine is a high-quality light source from JPT. The four-in-one handheld laser welding machine adopts an integrated design, with beautiful appearance and stable performance. The four-in-one handheld laser welding machine is easy to install and operate, and has high safety. Hand-held laser welding machine is equipped with wire feeding machine, which reduces the requirement of parts for clearance and further improves the welding quality. The four-in-one hand-held laser welding machine can also be used in conjunction with collaborative robots to fix the welding torch on the collaborative robot, reducing the labor intensity of the operator and improving the welding quality of the weld.

| Name | RAYLINE LASER Portable Water- cooled 4 in 1 Handheld Fiber Laser Welding + Laser Cutting+ Laser Cleaning Machine | |||

| Model | RA-HW1500W | |||

| Laser Power | 1500W | |||

| Laser Wavelength | 1064nm | |||

| Beam Diameter | 0.2-1.5mm | |||

| Volage (Customized) | 100-400VDC | |||

| Laser Welding Depth | 2.5MM | |||

| Laser Cleaning Width | 120MM | |||

| Laser Cutting Thicknees | 1MM | |||

| Pulse Frequency (Adjustable) | 1-100HZ | |||

| Aiming Positioning (Rote 360°) | Red Light | |||

| Fiber Length | 10M | |||

| Cooling Method | Efficient Cooling of Water Tank Water Circulation | |||

| Opreating System | Built in Colors touch Screen for Laser Welding+ Laser Cleaning +Laser Cutting | |||

| Language | English, Portuguese, Italian, Russian, French, German, Spanish, Polish, Korean, Turkish, Greek, Chinese, Czech, Japanese, Slovak, Thai, Vietnamese, Romanian ( Customized) | |||

| Application | Widely used in hardware industries such as cabinets, kitchens and bathrooms, staircase elevators, stainless steel homes,ect | |||

The existence of water-cooling systems is to meet the extreme requirements of industrial-grade laser equipment for power, stability and lifespan.

a. Support high-power and high-brightness lasers

This is the most fundamental advantage of water cooling. At present, high-power lasers ranging from several kilowatts to tens of thousands of watts generate heat that air cooling cannot handle and must rely on efficient water cooling systems.

b. Outstanding stability and reliability

Precise temperature control: It can ensure that the core components of the laser always operate within the optimal temperature window. The output power and beam quality of the laser are extremely stable. It will not cause energy fluctuations or "runaway focus" due to long-term operation and temperature rise, thus ensuring the high consistency of the quality of each solder joint in long-term and large-scale production.

c. High continuous working rate

The powerful heat dissipation capacity enables the water-cooled laser welding machine to support 24-hour continuous full-load production without shutting down for protection due to overheating. This is crucial for modern assembly lines.

d. Extend the service life of equipment

The optical components and semiconductor devices inside the laser are highly sensitive to temperature. A constant low-temperature working environment can greatly slow down material aging and performance degradation, thereby significantly extending the service life of the entire laser equipment.

e. Excellent beam quality

Temperature fluctuations can cause thermal lensing effects in laser crystals or optical fibers, deteriorating the beam quality. The water-cooling system can effectively suppress thermal effects, ensuring the high brightness and excellent focusing ability of the output laser, which is the key to achieving high-quality deep penetration welding.

f. Compact in size

It can be easily pulled from one workstation to another or flexibly scheduled between different workshops. The operation preparation is simple and plug-and-play.

The four-in-one handheld laser welding machine has the characteristics of fast welding speed, high efficiency, good welding effect, less welding consumables, long life and environmental protection. It can be widely used in kitchen utensils, door chimney guardrails, stair elevators, stainless steel furniture, hardware sheet metal, Billboards, craft gifts, auto repair, automobile manufacturing, rail transit, aerospace and other industries welding.